Every step of this process is monitored and optimised using specialised management software that maintains consistency throughout the fabrication process.

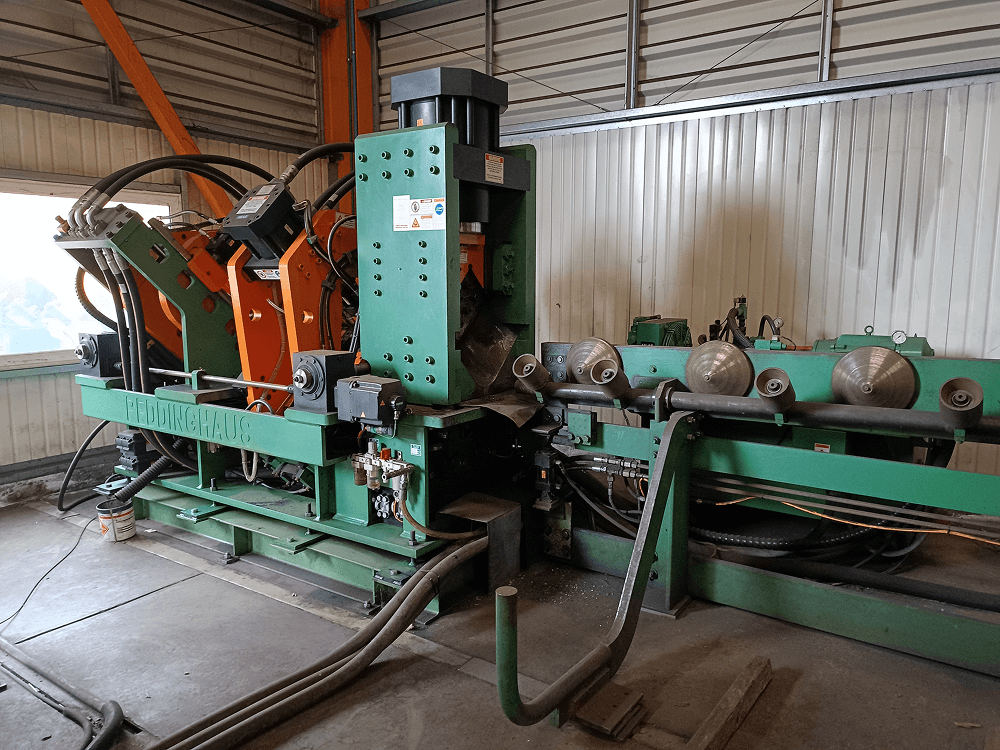

The processes that our CNC Beam Drilling Line carries out are:

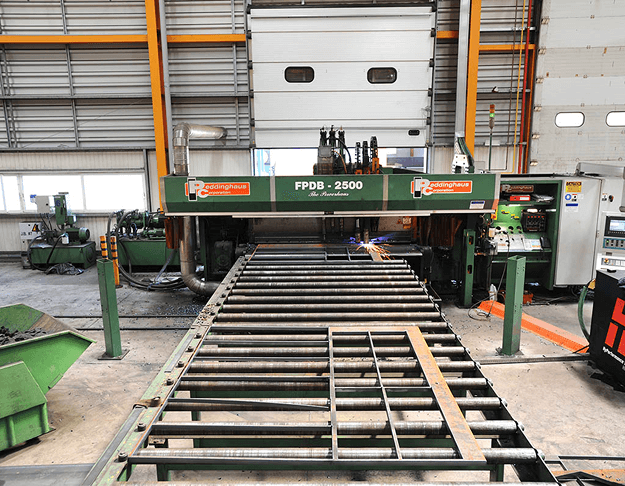

The processes that our CNC Beam Drilling Line for plates carries out are:

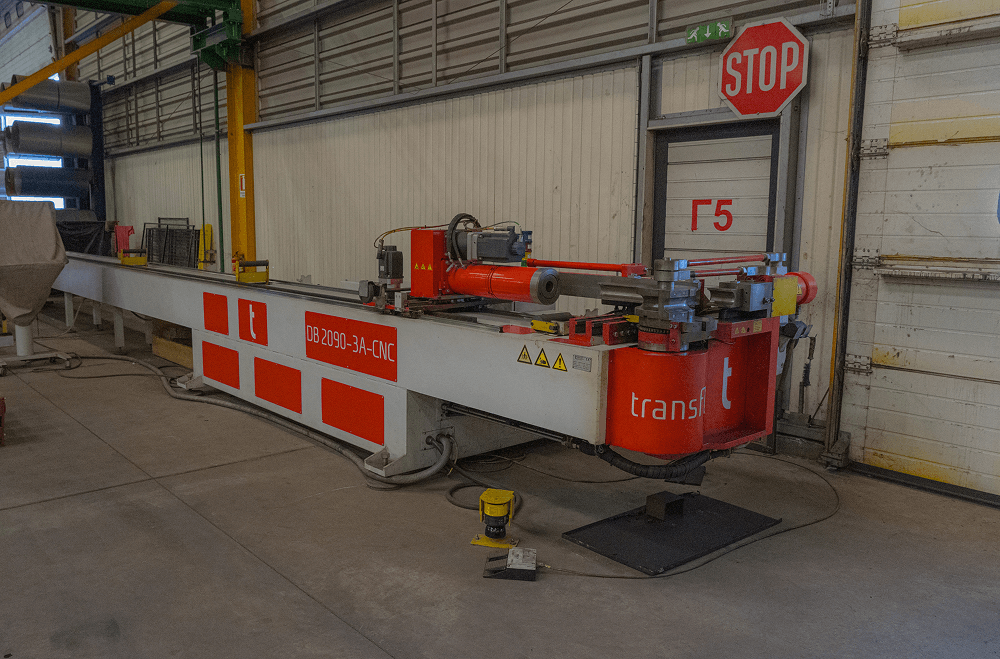

Using this machine, we carry out the following tasks:

Our high-end CNC plate processing stations carry out processes like:

Our modern plate processing system performs the following:

The modern T-Master helps us to carry out the following operations:

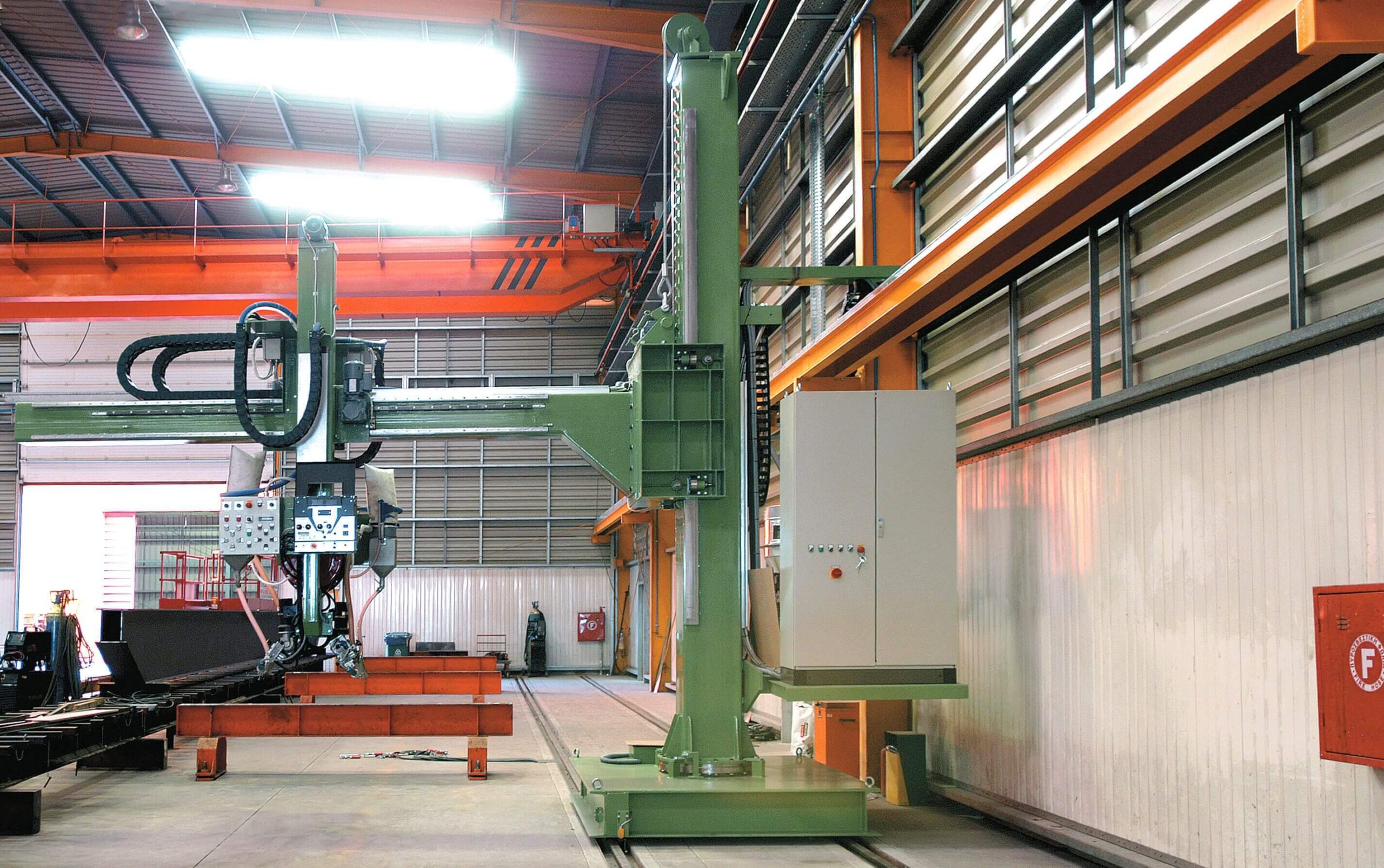

We can carry out the following operations through this welding line:

This machine helps us with the following operations:

This machine helps us to carry out the following operations with ease:

Our CNC milling machine makes the milling process easier as it has the following:

This tunnel is specially designed for carrying out processes like:

By integrating advanced monitoring systems, we uphold the highest quality standards while minimizing errors and material waste. This approach not only improves efficiency but also supports sustainable and cost-effective project execution.

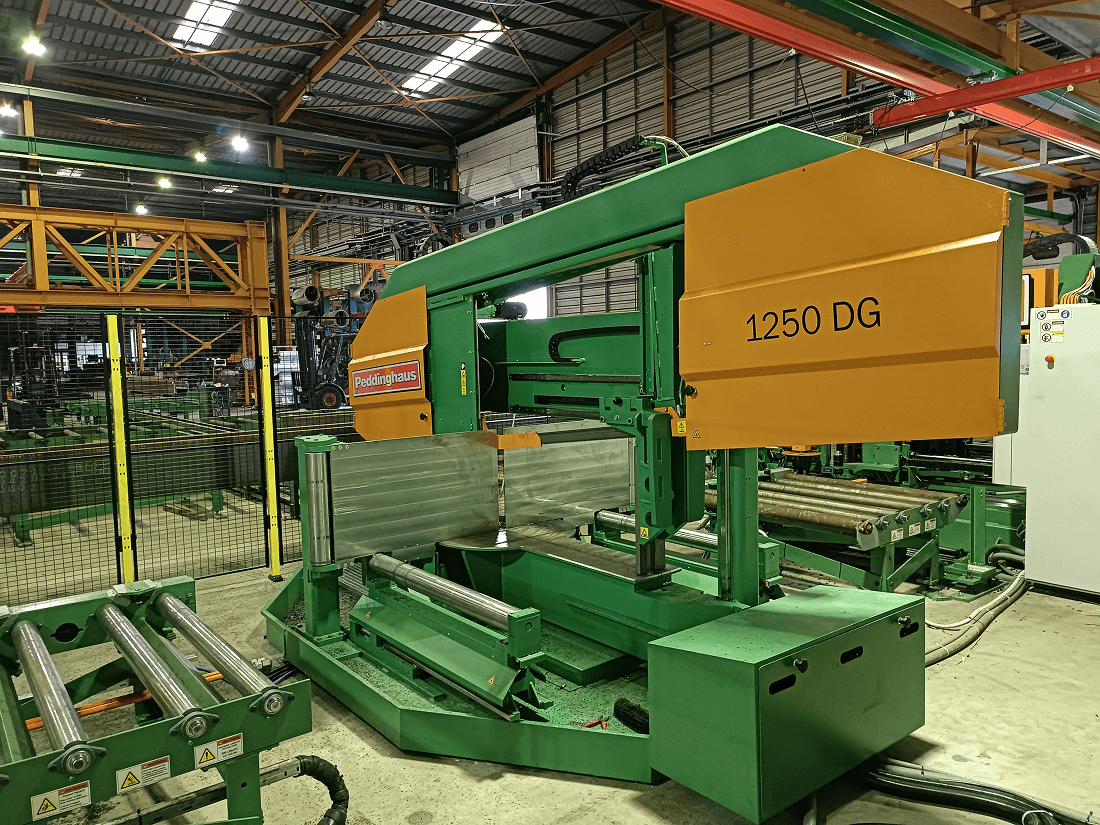

We possess this modern bandsaw for carrying out complex operations like:

The processes that our CNC Beam Drilling Line carries out are:

We possess this modern bandsaw for carrying out complex operations like:

The cutting machine on our premises helps us with the following:

With the CNC Plate drilling and punching machine, we can:

We can carry out the following operations through this welding line:

With metal sheet Cutting and Slitting line machine, we can:

We can carry out the following operations with this sheet metal folding machine:

Telephone

Head Office